NEWS CENTER

Jun. 26, 2025

Analysis of the application of pure steam generators in various industries

Pure steam generators heat water for injection or purified water to evaporate it into steam. In this process, water molecules change from liquid to gas and release a large amount of heat energy. The internal part is usually equipped with efficient heating elements and precise control systems to ensure the purity and stability of the steam. The steam generated is mainly divided into two types: saturated steam and superheated steam.

See More >>

Jun. 19, 2025

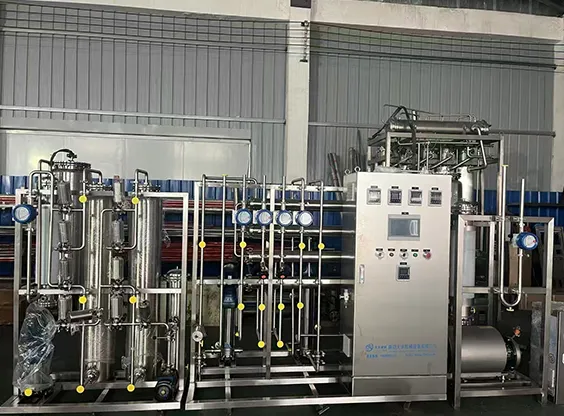

Process principle of pure steam generator

Pure steam generator is a device that uses purified water to produce pure steam. In the fields of pharmaceuticals, biotechnology, food processing, electronics industry, etc., it is widely used in various process flows, including sterilization, drying, cleaning and material production.

See More >>

Jun. 12, 2025

The structure and principle of the tubular multi-effect distilled water machine

The tubular multi-effect distilled water machine is a highly efficient and energy-saving pure water preparation equipment. Its core principle is to achieve the cascade utilization of heat energy through multi-effect evaporation series technology.

See More >>

Jun. 05, 2025

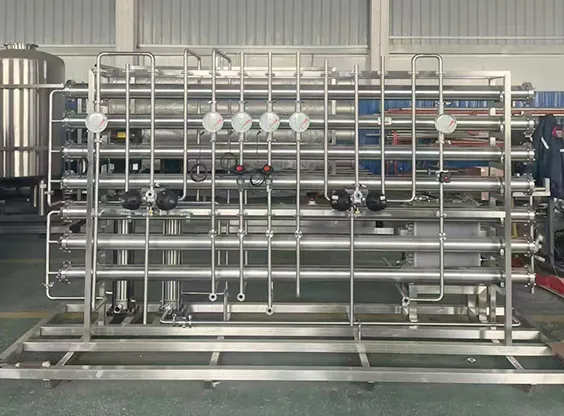

Process principle and characteristics of two-stage reverse osmosis pure water equipment

The raw water first passes through a multi-media filter to remove suspended solids, silt and other large particle impurities; then it passes through an activated carbon filter to absorb residual chlorine, odor and organic matter; some systems are equipped with a softener or antiscalant dosing device to reduce hardness and prevent subsequent membrane scaling. The pre-treated water also needs to pass through a security filter (precision filtration) to intercept tiny particles to ensure that the incoming water meets the requirements of the reverse osmosis membrane.

See More >>

May. 29, 2025

The main principles and uses of aseptic liquid preparation tank

Aseptic liquid preparation tank is a closed mixing container designed for industries with high hygiene standards. Its core principle is to establish and maintain an aseptic environment through a specific process to achieve safe preparation of materials.

See More >>